Pipe Corrosion and Defect Inspection

Key features

High accuracy dimensional analysis for critical sections

Medium to long range (0 - 1 km) robotic laser and camera crawler

Determine wall thickness loss in hard to reach locations

Full data management with proprietary point cloud software

Conventional internal root pass weld scanning

Calibrated and verified systems

Improved pipeline integrity

Map internal corrosion accurately

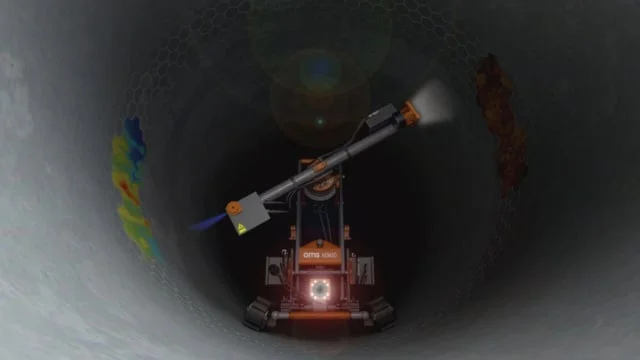

Internal pipe corrosion is difficult to detect, even with the best available ultrasonic techniques, and can cause critical problems in pipelines. OMS inspection systems accurately map internal corrosion, helping oil and gas companies reduce their costs, improve safety and extend pipeline lifetime. Our solution maps internal corrosion sites, using sensors and delivery mechanisms perfectly adapted for the task.

Camera and laser inspection

The AUGA.nomad system enters through a small aperture and expands when it reaches the optimal surveying location.

The system acquires data via stripe laser on a rotating head with a radial accuracy of ± 50µm or ± 100 µm

OMS proprietary point cloud software analyses single scans or multiple scans collected and stitched together

Camera images collected simultaneously for separate analysis and RGB overlay

Technique can also assess welds and internal pipe features such as liner wrinkling