Remediation

Efficient, targeted repair

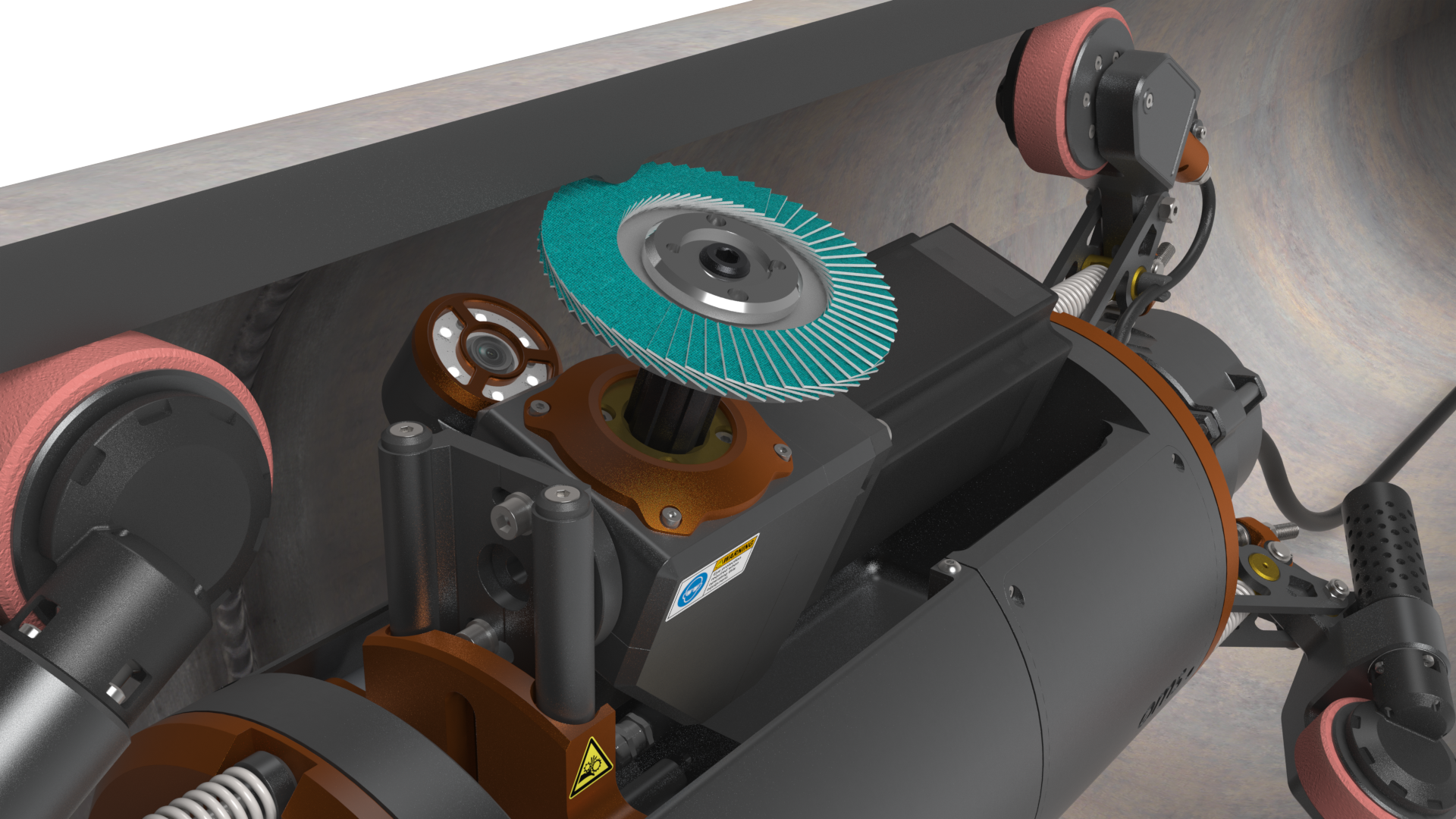

Inspection unit equipped with HD cameras and state-of-the-art laser sensors collects data that allows repair system to carry out targeted, localised repair. Rapid defect remediation allows production to proceed with maximum efficiency. Following repair, welds are rescanned before being verified as achieving project criteria.

Benefits:

Solve problems at an early stage

Laser sensors provide comprehensive range of data

Targeted repair reduces risk of parent material loss

No requirement to grind entire weld

Improve and strengthen surfaces

Deployment:

Variety of methods either at production stage or later

Integrates with other equipment

4” - 60” nominal pipe sizes

Suitable for CS and CRA pipe