Build higher quality assets with state-of-the-art remediation

Latest news: SmartGrind achieves Saudi Aramco verification

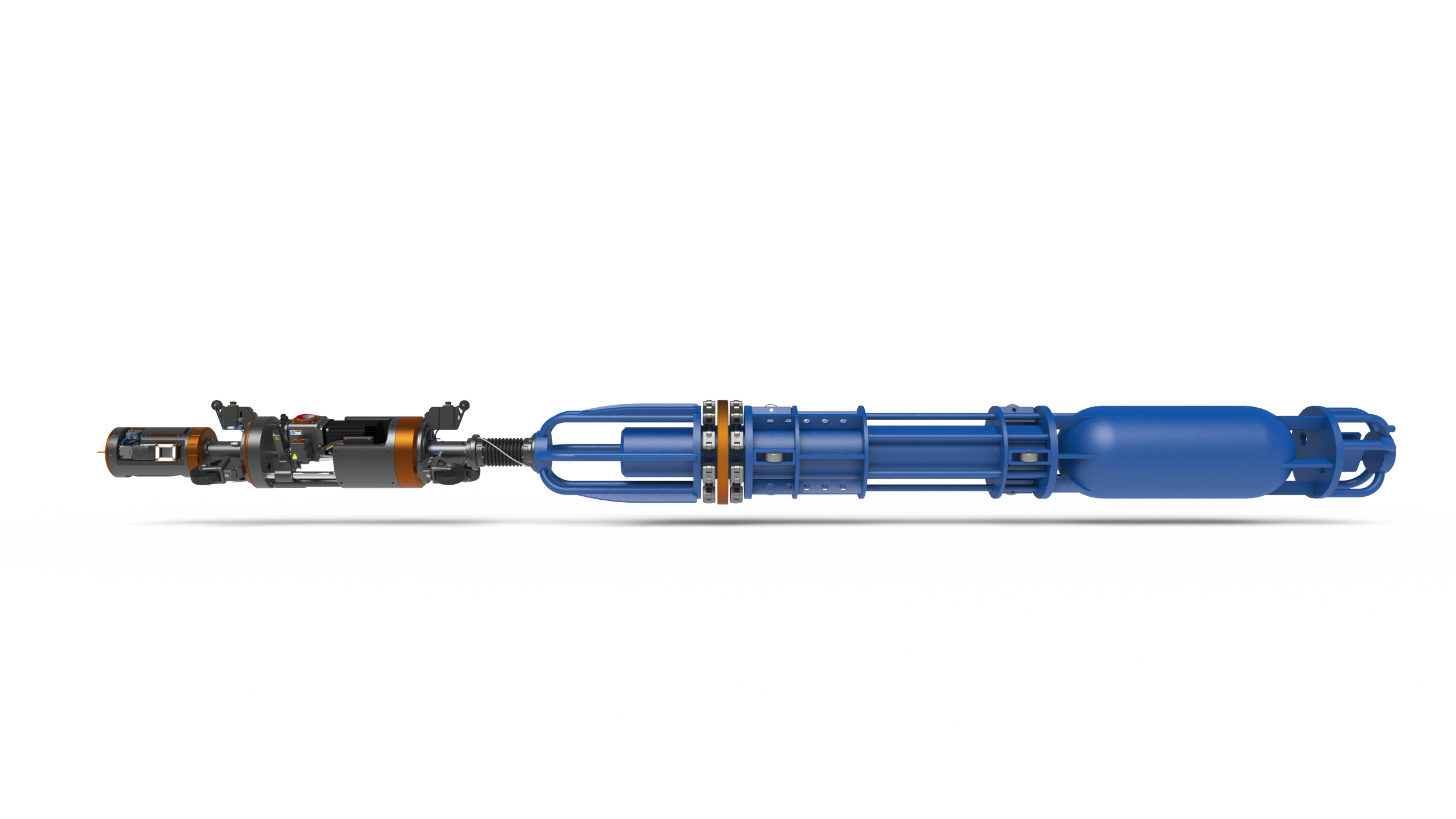

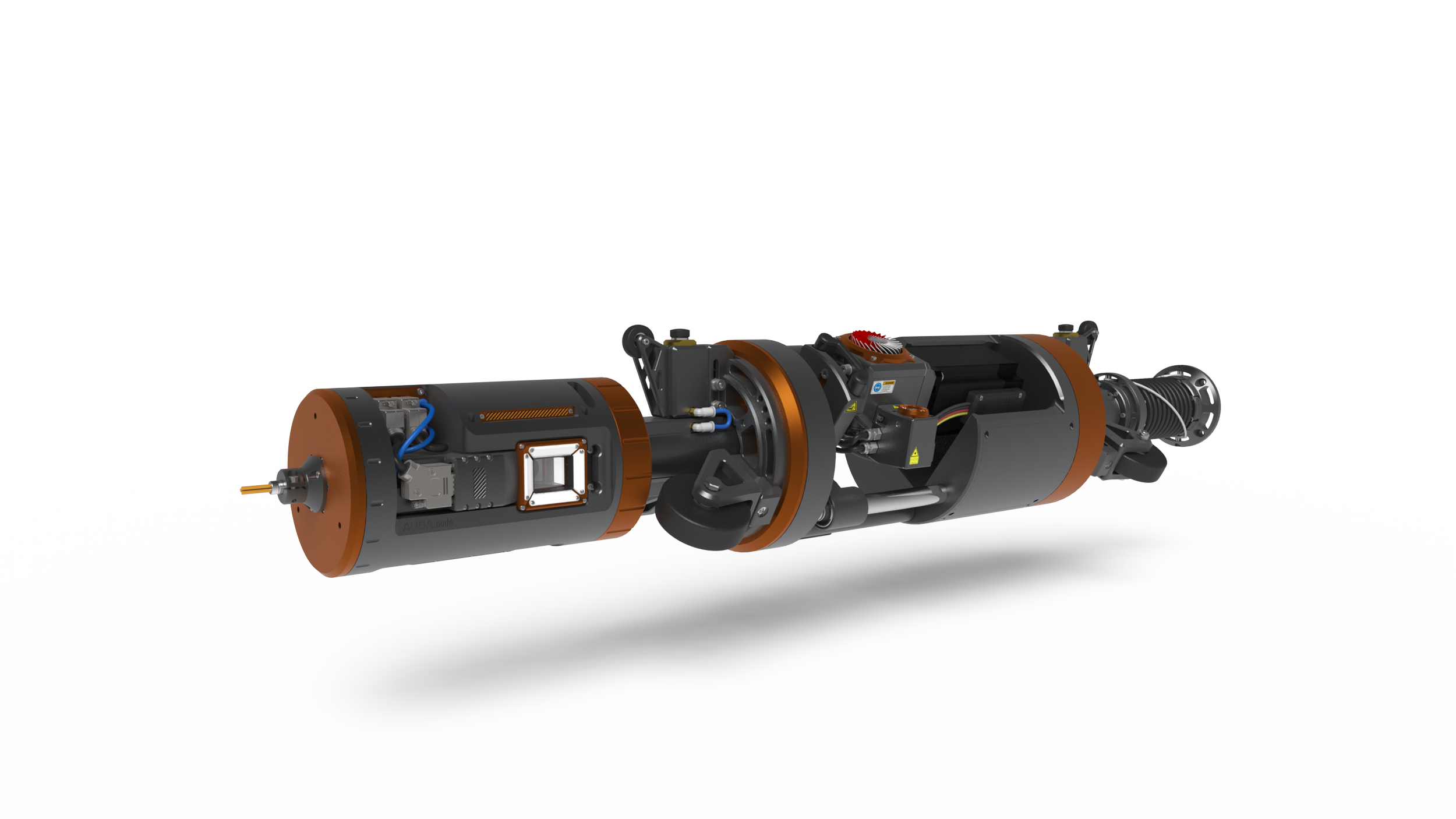

OMS SmartGrind solves weld defects at an early stage, ensuring potential problems are identified and remediated rapidly. A modular addition to our award-winning AUGA.node weld inspection system, SmartGrind uses a mounted flap disc to shape welds, which improves coatability, strengthens surfaces and helps ensure project specifications are met. Welds are accessed via robotic crawler or attached to the ILUC, eliminating the need for man-entry and thus improving safety. Production can proceed efficiently with reduced need for expensive and time-consuming cut-outs. A further modulation allows full flushing of the long-seam weld. Need more information? Contact our team.

Renewable and traditional energy

Identify and remove defects

Prepare surfaces

Improve safety

Reduce cut-outs and downtime

Remediation and inspection projects

Business benefits

Save money – install higher quality, longer lasting assets more efficiently

Increase productivity – less downtime, fewer time-consuming weld cut-outs

Improve safety – reduce requirement for man-entry in hazardous environments

Meet project specifications – achieve stringent criteria with ease

Why OMS?

We are world-leading inspection and remediation partners. OMS has been providing innovative solutions for the energy industry for more than 20 years. Our cutting edge technology and expert services have deployed on most major energy projects.