J-tube inspection

J-tubes guide export power cables from wind turbines to the seabed. An essential part of the wind turbine foundation structure, cables can be impeded, damaged and even blocked by excess weld penetration and internal pipe ovality. As energy regulators turn their attention towards renewable sources, more and more stringent standards are being applied with a particular focus on pipe shape and weld quality. OMS has developed a solution specifically aimed at solving these challenges in the wind energy industry.

Our award-wining weld inspection service collects real-time visual and laser data on the internal condition of your J-tubes, allowing clients to achieve project specifications, improve asset lifetime, make better quality decisions, reduce costs and mitigate risks. Our ground-breaking SmartGrind system can also identify and remediate weld problems in situ. Contact us for more information or a demonstration.

Visual and laser inspection

Make rapid, accurate in-field decisions with our self-contained laser and scanning system, which uses ultra HD cameras and state-of-the-art lasers to record comprehensive visual and dimensional information about a weld. Data captured provides a 3D map of the weld, indicating its full profile.

Attach to ILUC, deploy with AGILITY crawlers, or use push rods

Full 360º scan collects data in 25-45 seconds

Early detection of weld defects

Go/no-go indication

Data compatible with grinding or remedial action

Remediation

Identify and remediate weld defects with SmartGrind, a state-of-the-art grinding system that solves weld defects at an early stage, ensuring any potential problems are identified and remedied rapidly. Welds are accessed via robotic crawler or attached to the ILUC, improving safety as no man-entry is required. Production can proceed efficiently with reduced need for expensive and time-consuming cut-outs.

Deployment

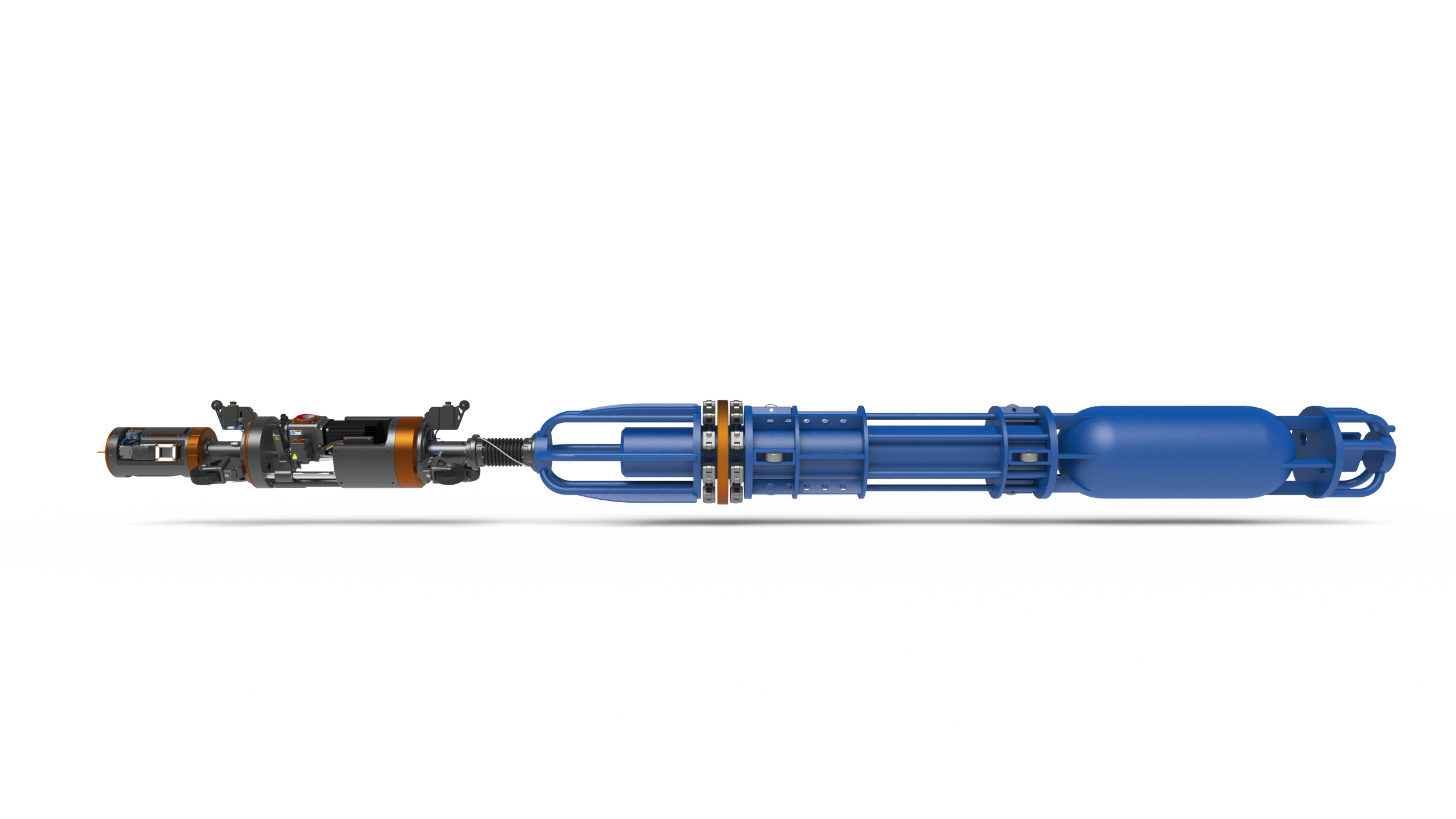

OMS weld inspection technology can access welds in critical and difficult-to-reach sections. Our system is deployed in a variety of ways - either via the AGILITY crawler range, or attached to the ILUC using the AUGA.reach linear actuators or via push rods. All deployment technology is robust and reliable and easily transportable. It is ideal for harsh marine environments and has been used widely and successfully in major global energy projects.

-

AGILITY.micro

Agile, high-powered crawler for small pipes. Internal diameters from 120-200mm (4” - 8”).

-

AGILITY.mini

Powerful crawler for pipes from 200 - 400mm (10” - 16”) internal diameter.

-

AGILITY.max

Our largest crawler for pipes up to 32” internal diameter.

-

AUGA.reach

Linear actuators automatically locate weld when attached to the ILUC.

-

ILUC

Attach directly to ILUC for in-line weld inspection.

OMS completes measurement work on Kasawari CCS project.