Oil and Gas

OMS has been providing services and products for the oil and gas industry for over 15 years. We offer pipeline inspection and measurement solutions that help our clients solve a range of pipeline challenges allowing corrective decisions to be made if necessary. Our systems use state-of-the-art robotics and crawlers, built specifically to handle harsh oil and gas environments, cutting edge tools and sophisticated software to identify defects in pipelines, manage construction effectively, meet stringent safety standards, expand automation and maintain asset lifetime integrity. Clients include oil exploration operators, engineering and welding contractors, pipe manufacturers and coating companies. OMS is an agile business with innovation at the heart of our approach. As three-time winners of the Queen’s Award for Innovation we have a wealth of experience developing innovative technology that helps oil and gas operators overcome pipeline problems. We often work in partnership with our clients to build solutions that match their needs perfectly. For more information about what is possible contact us.

Pipe-end measurement and fit-up

Pipes are scanned, measured, sorted and fitted-up using our SmartFit™ technology, which provides the most comprehensive fit-up information on the market. Pipes can be sorted and grouped, allowing even out-of-spec pipe to be used. Clients can achieve the best possible fit-up, even in complex critical pipeline sections such as spool pieces, risers and stalk tie-ins. All pipe data is amalgamated from mill to sea bed.

Weld inspection

Laser and camera inspection services available, including cleaning and surface preparation, weld scanning and remediation, pre-coating inspection and weld inspection. Pipes and welds are independently verified to meet project standards and all data is fully traceable.

Robotics

-

AGILITY.micro

Agile, high-powered crawler for small pipes. Internal diameters from 120-200mm (4” - 8”).

-

AGILITY.mini

Powerful crawler for pipes from 200 - 400mm (10” - 16”) internal diameter.

-

AGILITY.max

Our largest crawler for pipes up to 32” internal diameter.

-

AUGA.reach

Linear actuators automatically locate weld when attached to the ILUC.

-

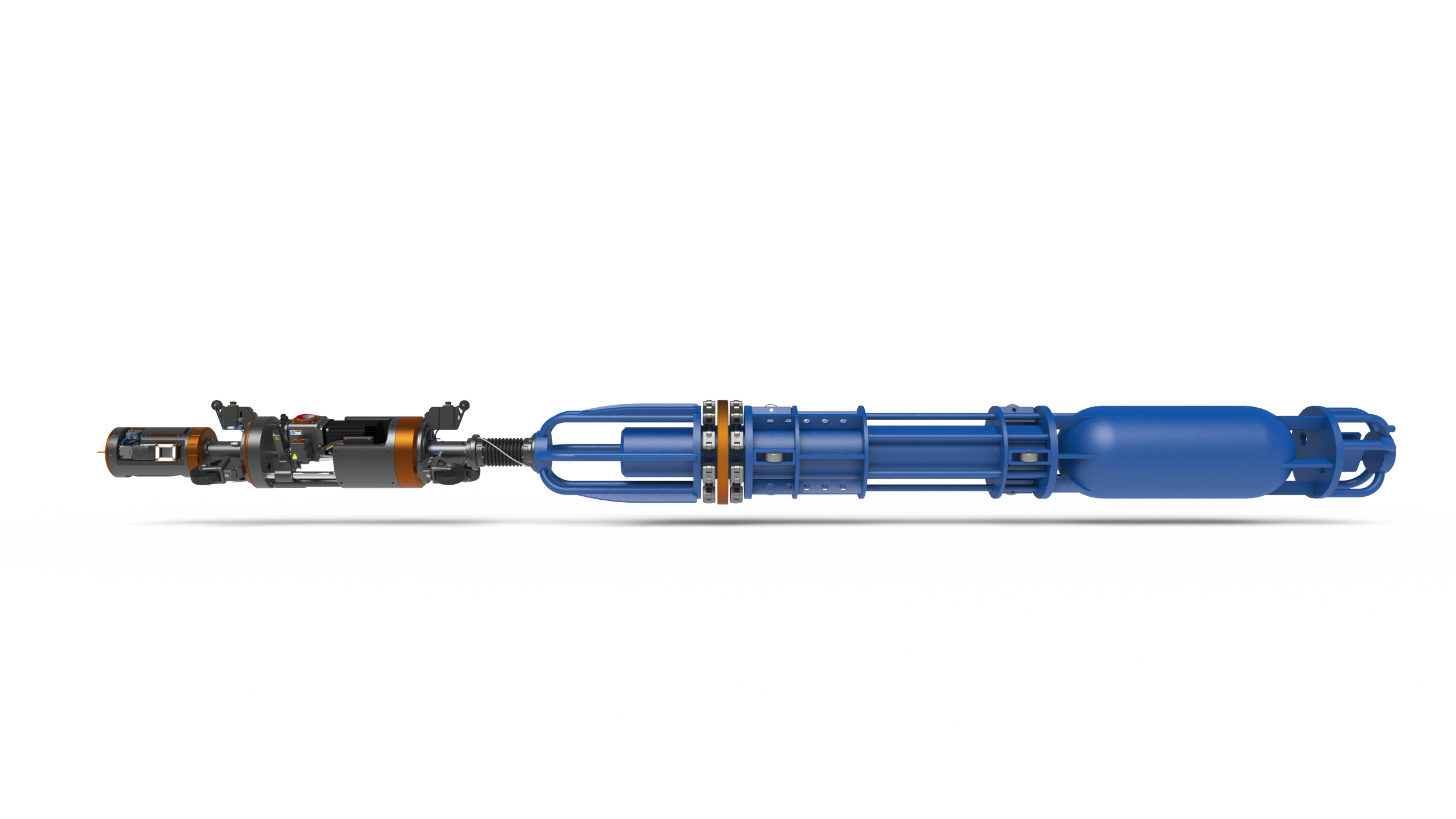

ILUC

Attach directly to ILUC for in-line weld inspection.

Projects

Our team was recently asked to attend a project where our client had encountered significant problems. Issues discovered while on the pipe-lay vessel caused problems which meant our client lost ten days of expensive vessel time. Our operators and technology were deployed and were not only able to remedy the issues, but managed to bring the project back to schedule, saving our client valuable time and enabling the installation process to progress smoothly. OMS offers agile solutions to client problems. Our portable technology and experienced operators mean we deploy rapidly and arrive on-site to solve problems as soon as possible. Contact us to find out how we can help.