Award-winning weld inspection technology

Specialist award-winning camera and laser inspection services for hard-to-reach areas within energy production. Services include cleaning and surface preparation, weld scanning, defect identification and remediation, pre-coating inspection and data analysis. Pipes and welds are independently verified to meet project standards and all data is fully traceable.

Our weld inspection services mostly deploy within the oil, gas and renewable energy sectors and we have successfully carried out a number of one-off inspections in other sectors. Contact us if you have technically challenging inspection requirements.

Weld inspection sectors

Oil and gas

OMS weld inspection technology is regularly used on major oil and gas projects worldwide.

Renewable energy

OMS inspects and repairs welds within major global renewable energy projects such as offshore wind farms.

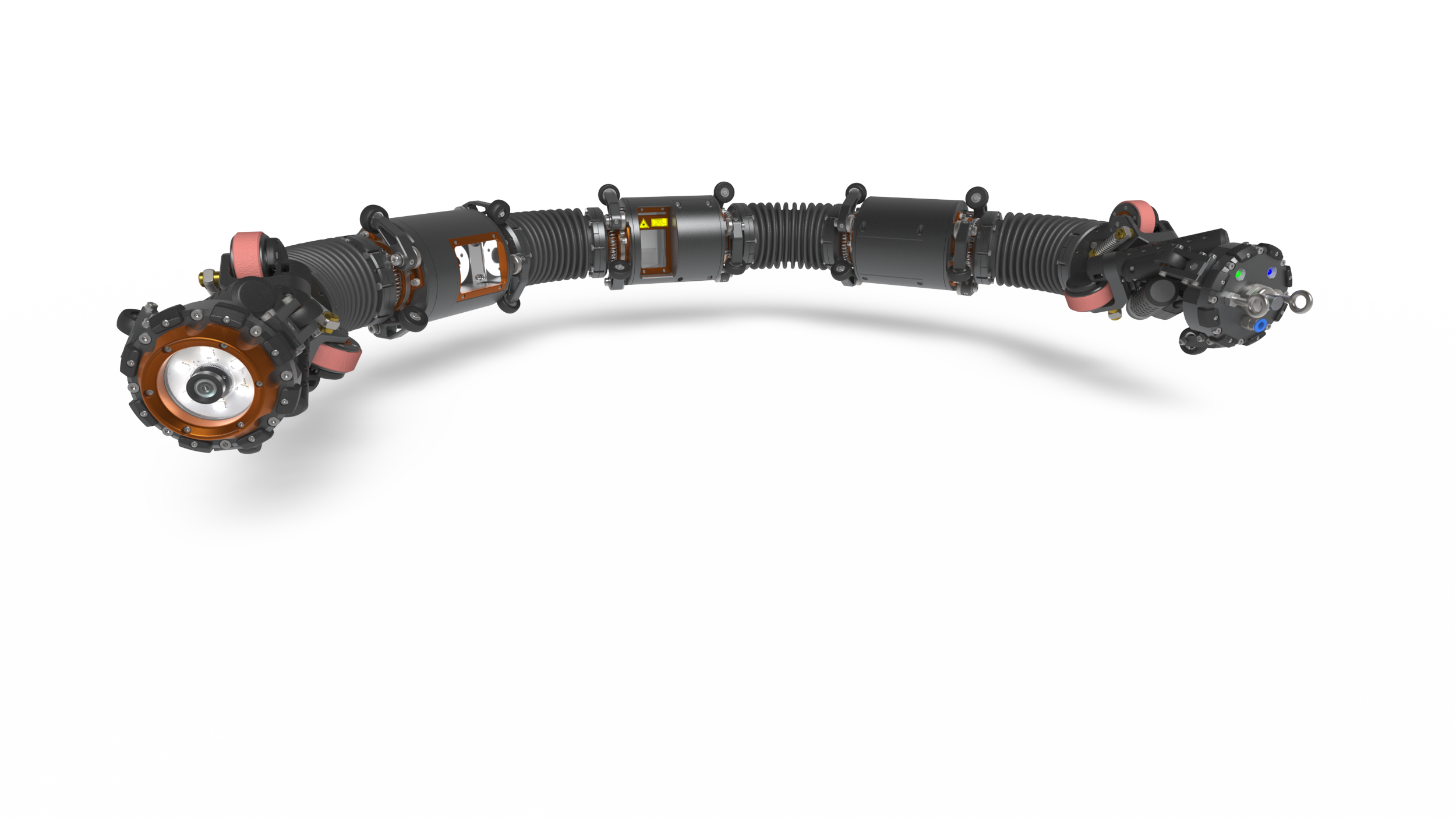

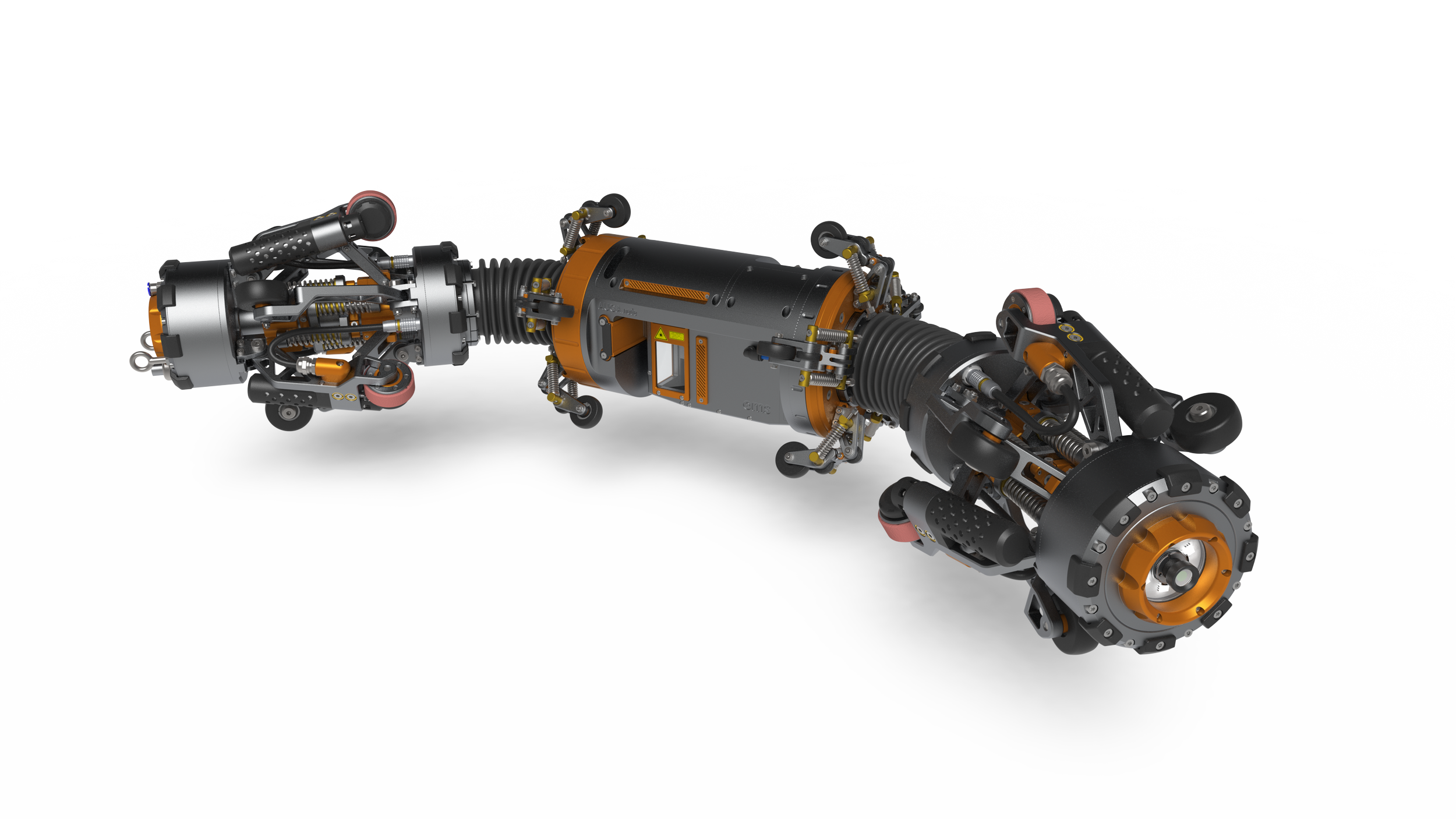

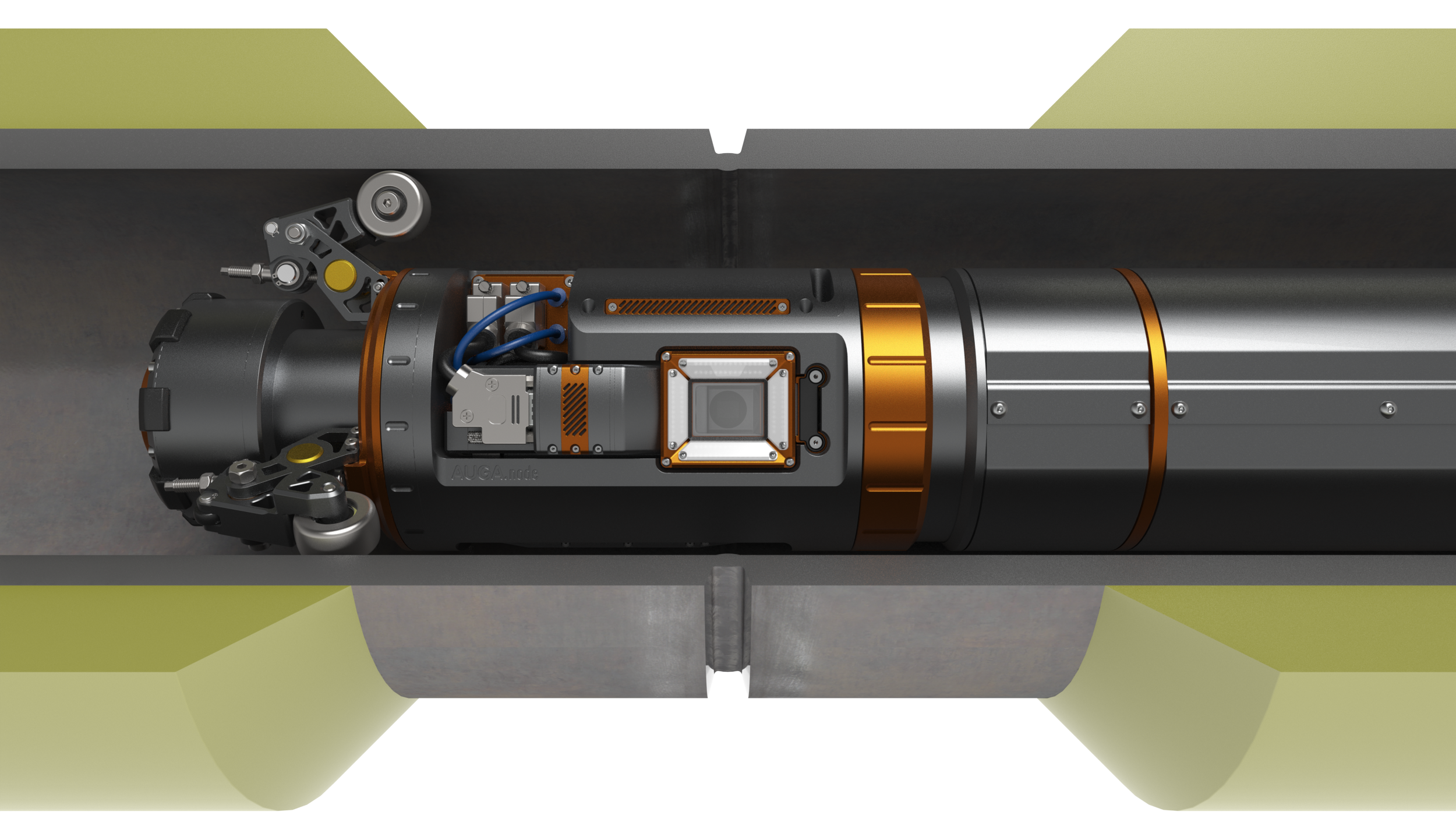

Visual and laser inspection: AUGA.node

Make rapid, accurate in-field decisions with our self-contained laser and scanning system, which uses ultra HD cameras and state-of-the-art lasers to record comprehensive visual and dimensional information about a weld. Data captured provides a 3D map of the weld, indicating its full profile.

Attach to ILUC, deploy with AGILITY crawlers, or use push rods

Full 360º scan collects data in 25-45 seconds

Early detection of weld defects

Go/no-go indication

Data compatible with grinding or remedial action

Deployment

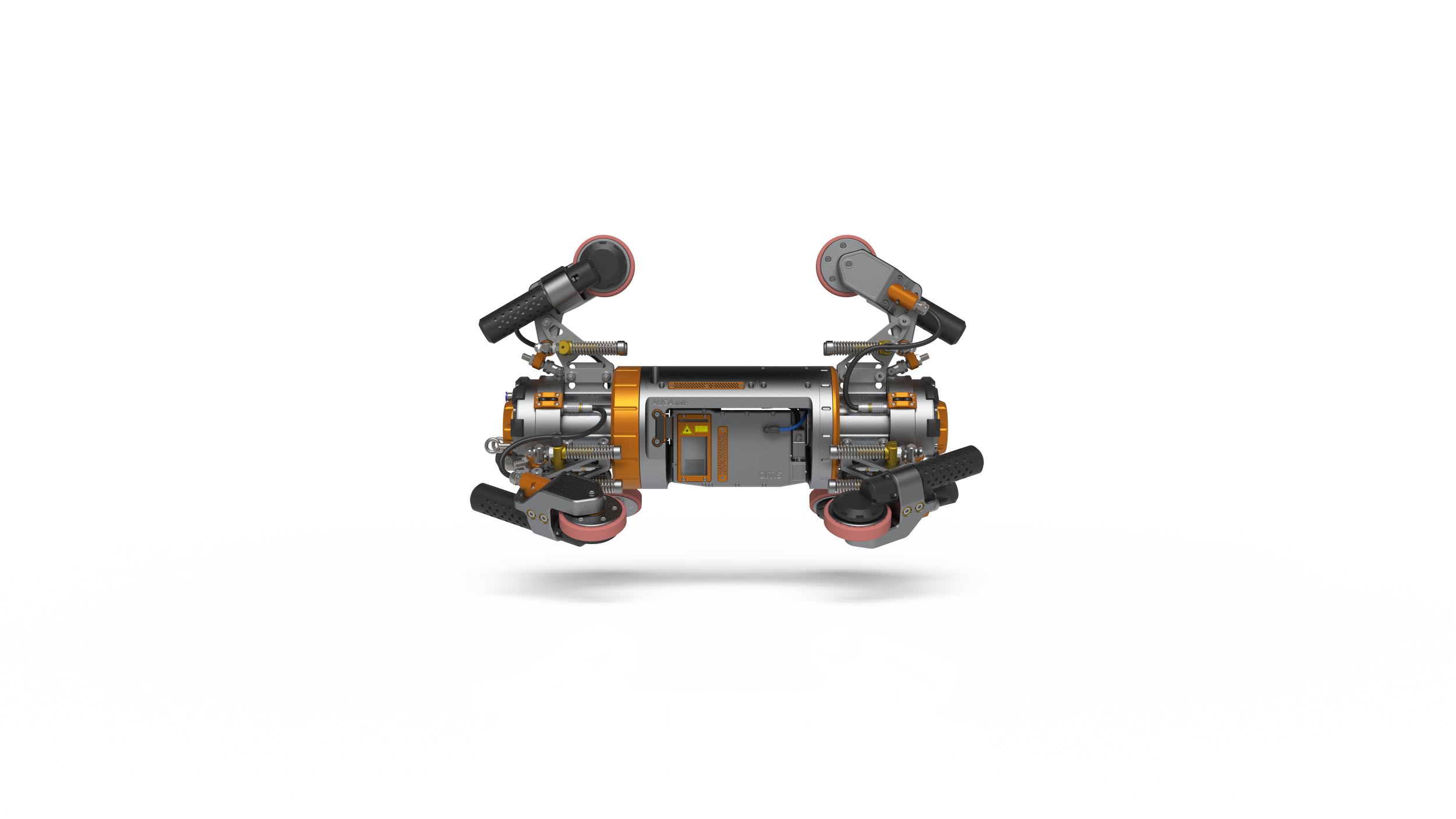

AGILITY crawlers

Access critical weld sections previously thought to be unreachable.

AUGA.reach

Linear actuators attach directly to ILUC for weld inspection in the firing line.

Pre-coating inspection

Ensure welds are ready for coating with our coatability inspection service. Welds are scanned, repaired with smart grinding unit if necessary, then rescanned and verified to meet project specifications. Extra-wide camera field-of-view, bespoke LED lighting and high accuracy lasers designed specifically to provide data required to confirm weld suitability.

Corrosion identification

Corrosion is one of the biggest challenges facing the energy industry, estimated to be responsible for around 25% of all pipeline failures. Identifying corrosion defects effectively is a vital part of asset management. Our inspection systems help clients detect and identify corrosion problems.

Laser measurement of internal pipe features

Visual record of pipe interior

Accurate, calibrated measurements

Early detection of defects for preventative action

Increased pipeline integrity

360° camera and laser scan

SmartGrind: weld remediation

Inspect, repair, inspect again:

Smart grinding unit resolves weld issues

Grinding and polishing system improves and strengthens surfaces

Post-grinding, inspection system confirms weld quality

Software and analysis: WeldAnalysis

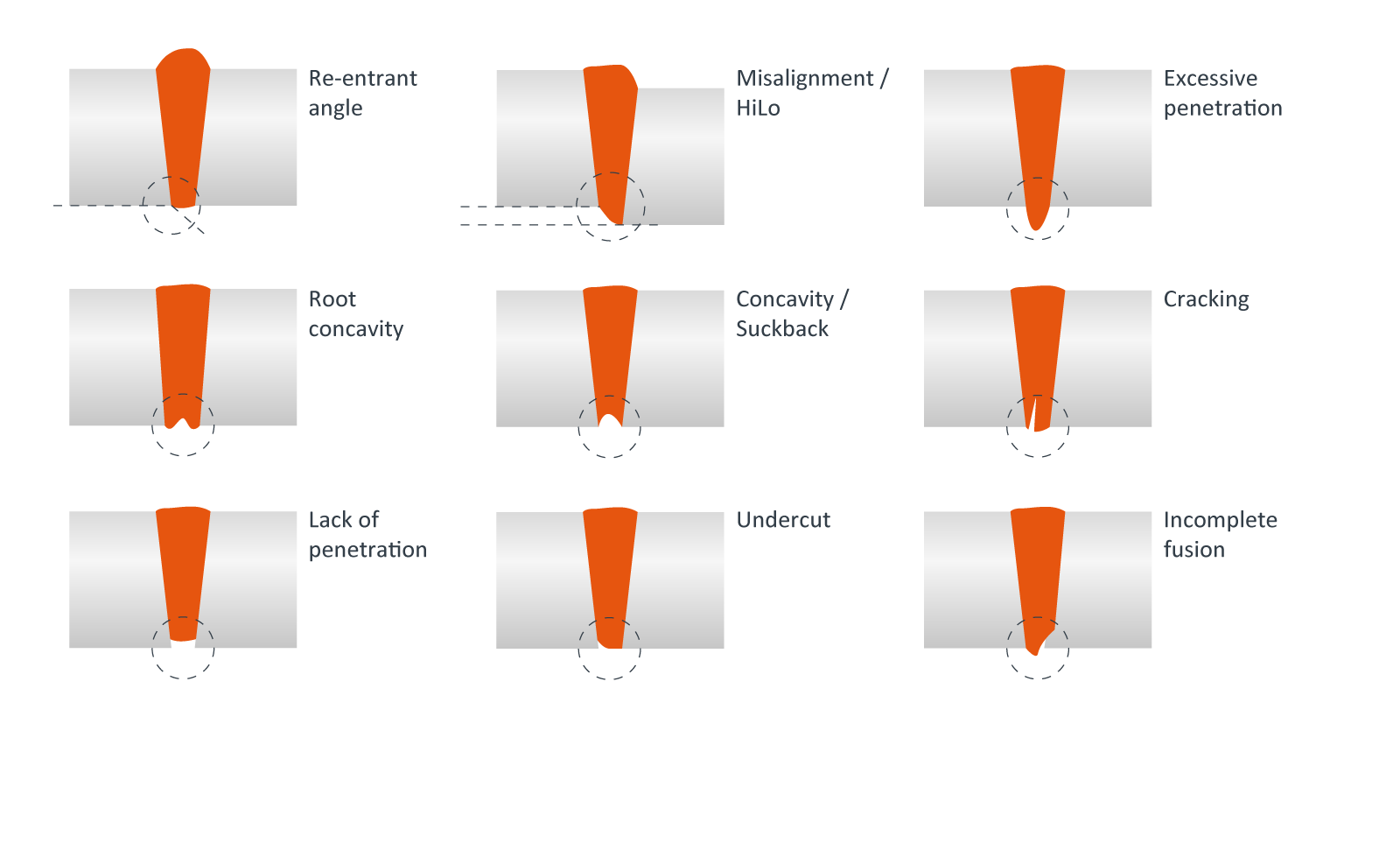

Assess wide range of defects

View laser and camera data in tandem

Rapid go/no go indicator

Results export to Excel

Independent verification and expert advice

Independent verification

As a reliable and trusted independent expert, OMS offers third-party inspection and verification services in pipes and pipe welds, both onshore and offshore. Our services and technology have inspected and verified tens of thousands of oil and gas pipes across the world.

Guide to weld inspection

Every stage in energy production depends on good quality welds. Each weld is a critical link on which the integrity of an entire system rests. Weld inspection plays a vital role in ensuring pipelines are strong, safe and long-lasting.